Monitoring Products, Sensors, and Data Collection Software for all Production Environments. |

|

|

|

IMPAX TSS 8 Productivity Monitor

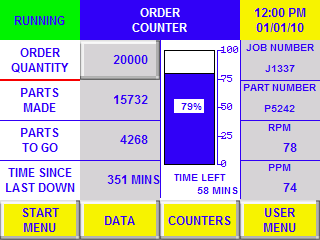

The IMPAX TSS 8 offers downtime analysis and production monitoring in an easy-to-use touch screen system. The TSS 8 automatically collects information on production totals, machine efficiency, and accumulated machine uptime and downtime. All occurrences of downtime, and the corresponding reasons, are tracked and archived. This system is available in a vivid color 8" touch screen display, either mounted in a NEMA-rated enclosure, or flush mounted into a control panel. Machine Efficiency Monitoring The TSS system is capable of collecting critical process data from virtually any machine that runs in a manual or automatic mode. This includes cold headers, thread rollers, stamping presses, screw machines, injection molding machines, multi-slides, spring coilers, forging presses, assembly/insertion machines, packaging and printing applications, drills/taps, saws, and more. The system analyzes and displays the machine's run condition and other information. In the event of a machine/process stop, the unit automatically converts to downtime entry mode. Operators must select from pre-defined downtime reasons in order to restart the machine, so all downtime information is accurate. The touch screen interface displays a summary of downtime occurrences and minutes for each downtime reason, uptime and downtime minutes, productivity, tool and maintenance counters, and machine efficiencies (including OEE, Overall Equipment Effectiveness). Productivity Data Collection

The TSS 8 tracks: (click for more information)

The 8" screen on the TSS 8 is Windows CE-compatible, so in the touch screen interface may also be used for viewing PDF files and other office documents. Documents can be stored locally in the TSS's memory, or loaded from a networked file server or PC. Operators can use this feature to refer to part diagrams, machine setup instructions, and other types of documents right at the machine. More information is available in the TSS CAD Drawings PDF. Networked Data Collection

IMPAX TSS monitors can be networked over wired or wireless Ethernet, to deliver accurate, real-time data to office computer networks and production databases. Additionally, IMPAX TSS-NET software provides easy-to-use and powerful analysis tools for collected data. Shop-floor data from the TSS monitors can be displayed in real-time, or transferred into a database program for further evaluation and report generation. Please see the TSS-NET Software page for more information. There are additional options to displaying and accessing TSS productivity data throughout the company. Shop floor status data can be displayed in large overhead display boards, or on flat panel displays throughout the shop (TSS Large Displays PDF). TSS monitors can also be accessed remotely, to view their status or enter new part numbers or counter goals from across the network (TSS Remote Access PDF). Product DetailsSpecifications:

Available I/O:

Product Comparison Grid (overview of TSS features, by model) Request More Information, or a Quote Comparison Grid of IMPAX TSS Monitors |

|