Monitoring Products, Sensors, and Data Collection Software for all Production Environments. |

|

|

|

IMPAX TSS-NET Software

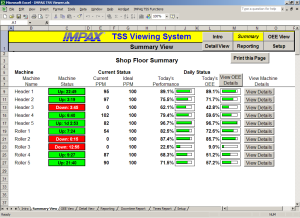

IMPAX TSS-NET is a suite of PC software for status viewing, data collection, reporting, and setup of IMPAX TSS monitors. TSS-NET lets you monitor production statistics in real time, and view uptime and downtime data as it occurs on the shop floor. The system can connect any TSS monitors to one or more PCs across a wired or wireless Ethernet network, providing live data to any networked PC. TSS-NET also displays shift and daily reports that used to take days or weeks to compile. Managers can get real-time information about the shop floor machinery, they they can use to fine-tune the manufacturing process as needed, resulting in increased productivity and improved quality. Viewing Status This activity gives real-time tracking of each machine's status, each operator's status, and each part's status, all from any networked PC.

Shop floor information is shown including: (click for more information)

All real-time information screens have a "Print Screen" function, making it easy to document the information currently displayed. Data Collection IMPAX TSS-NET supports automatic data collection. Machine data, downtime occurrence logs, and part and operator data are collected periodically throughout the day. Data can be collected automatically across a serial or Ethernet network (wired or wireless), or by directly connecting to each TSS unit once daily. After collection, the data can be analyzed and reviewed via the TSS-NET program. This data is stored in a comma-delimited format so that it can be imported into reporting programs or streamed into database programs, for further analysis and evaluation.

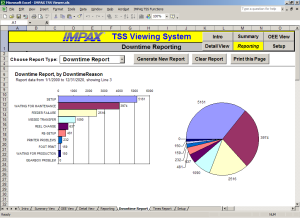

Reporting TSS-NET also offers customizable reports for all collected data. Lists and summaries of the data can be generated and printed, using Excel macros and pivot-table technology. Additionally, the comma-delimited files can be imported to a program of the user's choice, for total flexibility to do further analysis and reporting. Some of TSS-NET's reporting options include: (click for more information) System Setup TSS-NET's setup mode allows entry and editing of all TSS parameters. It is easy tp customize machine names and dowwntime reasons for each installation. Pending part and run rate information can also be entered, and sent out to the TSS monitors on the shop floor. Finally, all TSS-NET settings can be customized, to tailor how and when the system collects data, logs TSS messages, and more. Specifications:

Request More Information, or a Quote Return to Productivity Monitoring |

|