|

|

|

IMPAX-SK Mandonic

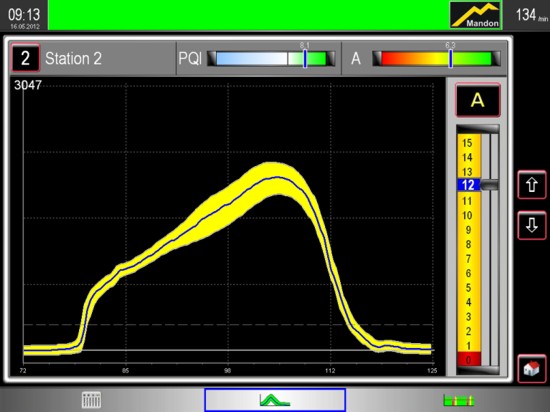

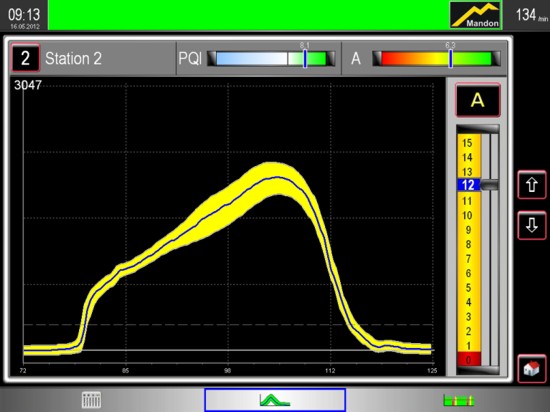

IMPAX/SK Mandonic auto enveloping enhances error detection and avoids unnecessary machine shut downs. The new Mandonic auto-enveloping system has been developed to provide a solution to the old conflict between detecting errors reliably but avoiding machine shut downs without reason. It is obvious that it takes envelope limits as tight as possible to detect the often minute changes in the force pattern typical for small defects in cold forming. On the other hand, the machine used to be stopped frequently for no apparent reason other than the normal process variation or sudden small signal changes. The force curve would leave the envelope limits but no true error could be found. Hence, the operators would change the envelope band to a coarser setting, but the capability to detect smaller errors would suffer at the same time. Mandonic auto-enveloping solves this problem. All mathematical formulas used to calculate the envelope limits have been re-thought and completely reprogrammed by our engineers. The typical variation inherent in any process is now observed more intensely and entered into the dynamic calculation of the envelope bands. The improved dynamics in establishing the envelope limits is also emphasized by the fact that sensitivity now can be adjusted in 15 steps rather than the older 9 step technique. Most processes can now be monitored reliably with extremely fine sensitivity without nuisance machine stoppages.

|